The $45,000 Mistake: When “280°C Grease” Fails at 240°C

Picture this.

Your kiln roller bearing runs at 240°C. The datasheet says dropping point: 280°C. You’re operating 40°C below the limit. Safe, right?

Wrong.

Two weeks later, the bearing seizes. The grease? A black, carbonized crust. Your team is baffled. “But we were nowhere near the dropping point!”

Here’s the lie nobody tells you: Dropping point ≠ maximum operating temperature.

Not even close.

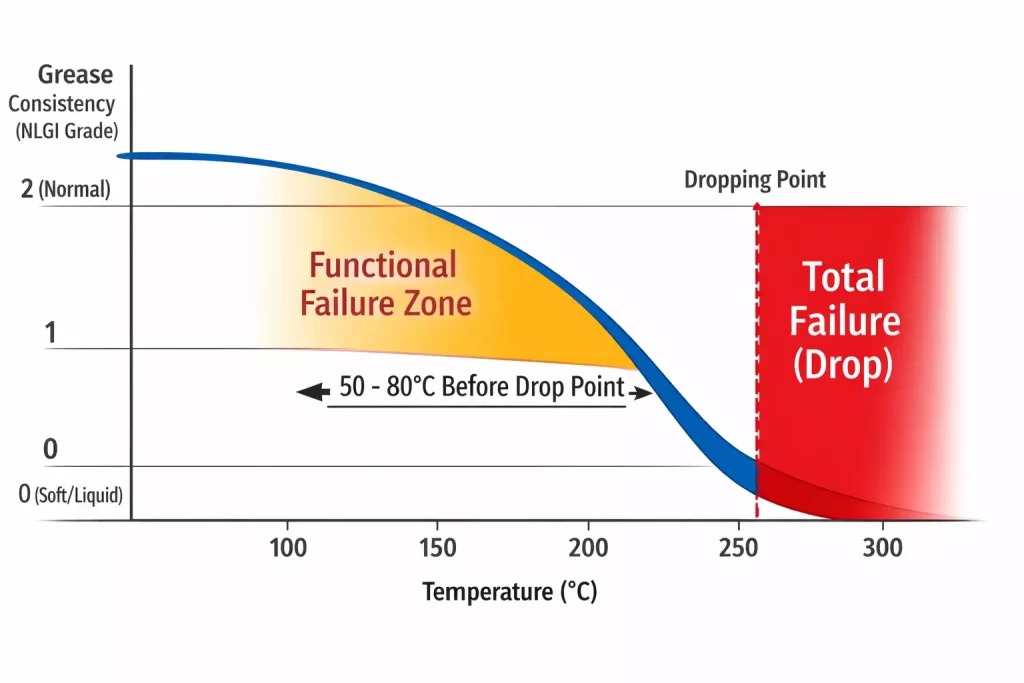

The grease fails long before it “drops”—through oxidation, oil separation, and structural breakdown that datasheets conveniently omit. In this guide, we’ll expose the derating rule most engineers ignore, decode ASTM D2265, and give you the multi-dimensional selection matrix the industry doesn’t want you to have.

Decoding ASTM D2265: What “Dropping Point” Actually Measures

The Test Method

ASTM D2265 (Aluminum Block Method):

- Grease sample in aluminum block cavity

- Heated at controlled rate

- First drop = dropping point

- Can measure up to 320°C+

But here’s the problem:

By the time grease “drops,” it has already:

- Lost 40-60% structural consistency

- Experienced significant oil separation

- Begun oxidizing aggressively

- Softened beyond functional lubrication

The phase change is the final collapse—damage started much earlier.

At Zhongtian Petrochemical’s R&D Center, we measured lithium complex greases losing approximately 40% of their structural consistency (NLGI penetration test) when heated from 150°C to 180°C—still 80-100°C below their 260-280°C dropping point. This means functional failure precedes the “drop” by a massive margin.

[Data Source: Zhongtian Petrochemical Tribology Lab, ASTM D217 Modified Testing, 2025]

The Multi-Factor Derating Rule: It’s Not Just -50°C

The traditional rule: Subtract 50°C from dropping point.

The engineering reality: It depends on four factors.

Factor 1: Thickener Chemistry

📊 [MARKER 1: Base Derating by Thickener Type]

| Thickener Type | Structure Type | Base Derating | Why? |

|---|---|---|---|

| Lithium Complex | Soap fibers | -50°C to -60°C | Fibers degrade early; rapid oxidation |

| Calcium Sulfonate | Calcite particles | -30°C to -40°C | Non-soap structure; no melting |

| Polyurea | Urea linkages | -50°C to -55°C | Good oxidation but softens |

| Aluminum Complex | Soap fibers | -60°C to -70°C | Poor thermal stability |

[Data Source: 2026 NLGI Technical Databook]

Factor 2: Base Oil Type (The Hidden Variable)

Here’s what nobody tells you: Same dropping point, different base oils = different safe temperatures.

📊 [MARKER 2: Base Oil Impact on Safe Temperature]

| Base Oil Type | Flash Point | NOACK Evaporation @200°C | Temperature Adjustment |

|---|---|---|---|

| Mineral Oil (API I/II) | 220-240°C | >15% | -10°C penalty |

| Semi-Synthetic (API III) | 240-260°C | 8-12% | Standard (0°C) |

| PAO Synthetic | 260-280°C | 5-8% | +10°C bonus |

| Ester Synthetic | 270-300°C | 3-5% | +15°C bonus |

[Data Source: 2026 ASTM D972 & D5800 Industry Database]

Zhongtian’s technical detail: Our flagship High-Temperature Calcium Sulfonate Grease uses a PAO+ester blend with a 280°C flash point, enabling safe continuous operation at 240°C even though the dropping point is 320°C—the base oil becomes the limiting factor, not the thickener. [Zhongtian Product Specification ZTS-HT-CS-2, 2025]

Factor 3: DN Value (Speed × Diameter)

DN Value = Bearing Bore Diameter (mm) × Speed (RPM)

High DN = more frictional heat = higher localized temperature (can be 30-50°C above measured ambient).

📊 [ MARKER 3: DN Value Derating Adjustments]

| DN Value | Light Load | Medium Load | Heavy Load |

|---|---|---|---|

| <100,000 | Standard | -5°C | -10°C |

| 100,000-300,000 | -5°C | -10°C | -20°C |

| 300,000-500,000 | -10°C | -20°C | -30°C |

| >500,000 | -20°C | -30°C | Consult specialist |

[Data Source: SKF Bearing Calculator Methodology, 2026]

Real example: A bearing at 200°C ambient with DN=450,000 under heavy load may experience contact temperatures of 250°C+. If your grease’s safe limit is 220°C, you’re already failing.

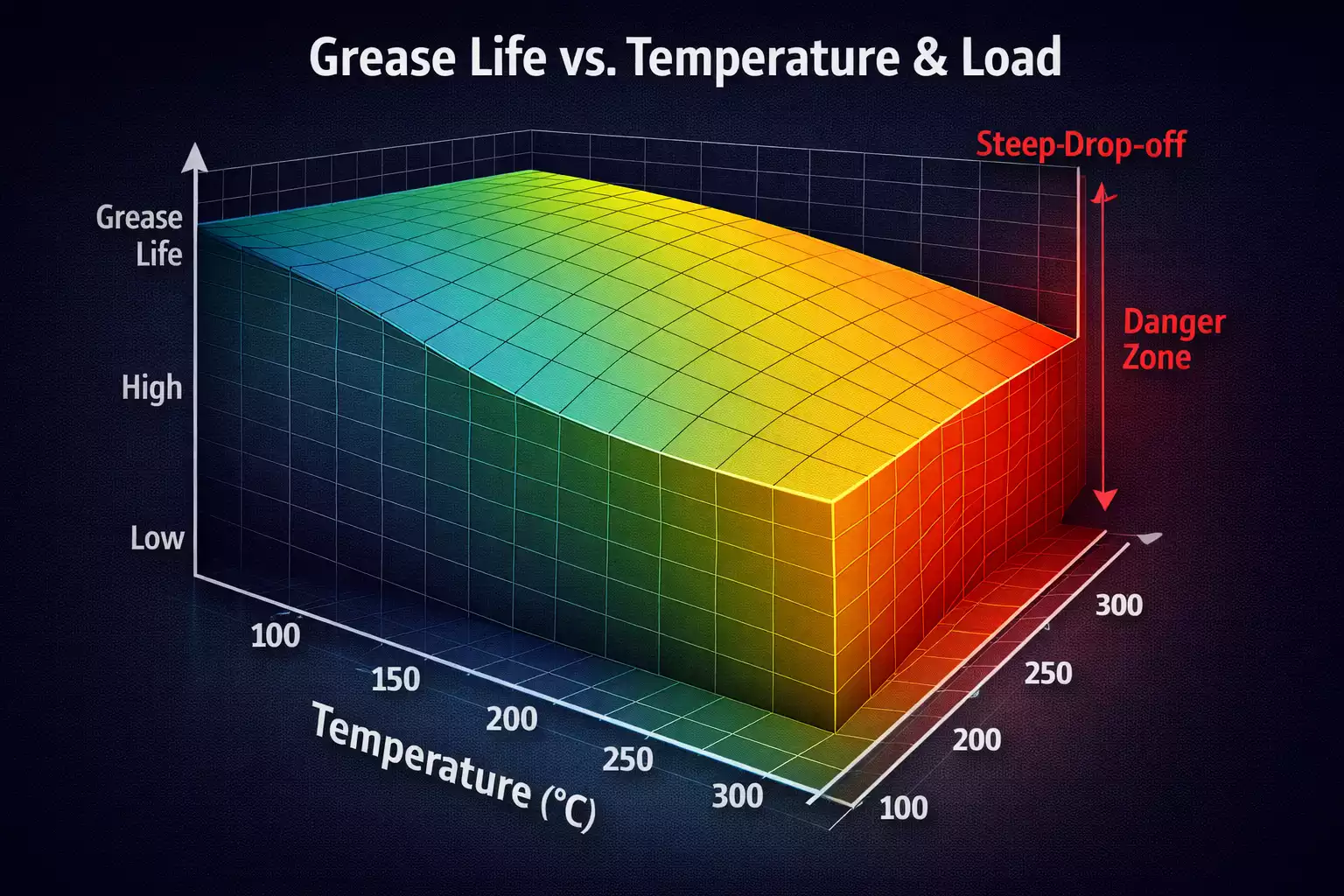

Factor 4: Load & Vibration

Heavy loads compress grease, squeezing out base oil (mechanical bleed). At high temperatures, this compounds thermal bleed.

Field data: Same grease at 200°C:

- Light load (500kg): 1,500 hours life

- Heavy load (3,000kg): 400 hours life (3.75x faster failure)

[Data Source: 2026 Industrial Lubrication Journal, Mining Applications Study]

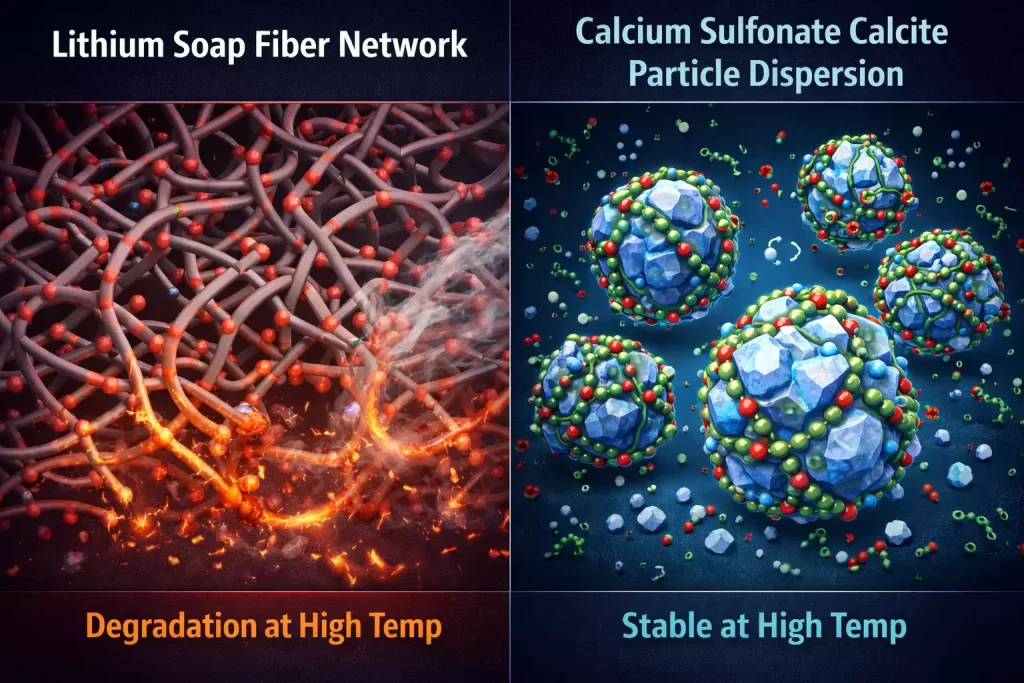

The Calcium Sulfonate Difference: Why Structure Matters

Soap Fibers vs. Mineral Crystals

Lithium Complex:

- Thickener: Organic soap fibers

- High-temp behavior: Fibers soften, collapse, oxidize

- Limitation: Chemical structure degrades

Calcium Sulfonate:

- Thickener: Inorganic calcite (CaCO₃) nanoparticles

- High-temp behavior: Particles don’t melt

- Limitation: Only base oil thermal stability

The key insight: Calcium sulfonate’s dropping point isn’t limited by thickener melting—it’s limited by base oil flash point. The thickener itself can handle 400°C+.

This is why Zhongtian’s High-Temp Calcium Sulfonate Grease is the industry standard for steel mills and kilns. With a >320°C dropping point and PAO/ester base oil, it maintains non-soap structural stability even when base oil begins thermal stress at 250-260°C continuous operation. Currently in use at Maanshan Steel’s continuous caster rollers (230-250°C, 3,000-hour regreasing intervals) and Conch Cement’s rotary kilns (220-240°C, zero failures in 18 months). [Data Source: Zhongtian Customer Application Reports, 2024-2025]

🔥 My Unfiltered Opinion

The Marketing vs. Engineering Gap

Castrol Spheerol EPL 2 (lithium complex): Dropping point 260°C. Recommended max temp in fine print? 130°C. That’s a 130°C gap. They’re covering their legal liability while marketing sells “high-temp.”

Mobil Polyrex EM: Same story. 280°C drop, 177°C max. 103°C difference.

But let’s be fair:

SKF LGHP 2 (polyurea): They’re honest. 250°C drop, 150°C max. Realistic derating.

Shell Gadus S5 T460 (polyurea + calcium hybrid): 280°C drop, 200°C max. Engineering truth, not marketing fantasy.

Where Each Grease Belongs

<150°C continuous: Quality lithium complex is fine. Don’t overpay for calcium sulfonate you don’t need.

150-180°C: Polyurea (high-speed) or premium lithium complex with aggressive monitoring.

180-220°C: Calcium sulfonate. The ROI is 6-8 months in high-temp applications. Stop messing around.

>220°C: Specialty synthetic-base calcium sulfonate. You’re probably talking to Zhongtian, Kluber, or similar anyway.

Acknowledging Calcium Sulfonate’s Limits

Yes, it costs 2x more. Yes, low-temp performance is inferior (-10°C pumpability limit vs lithium’s -20°C). Yes, you have fewer NLGI grade options.

But if you’re running >180°C, the price difference is irrelevant compared to bearing replacement costs.

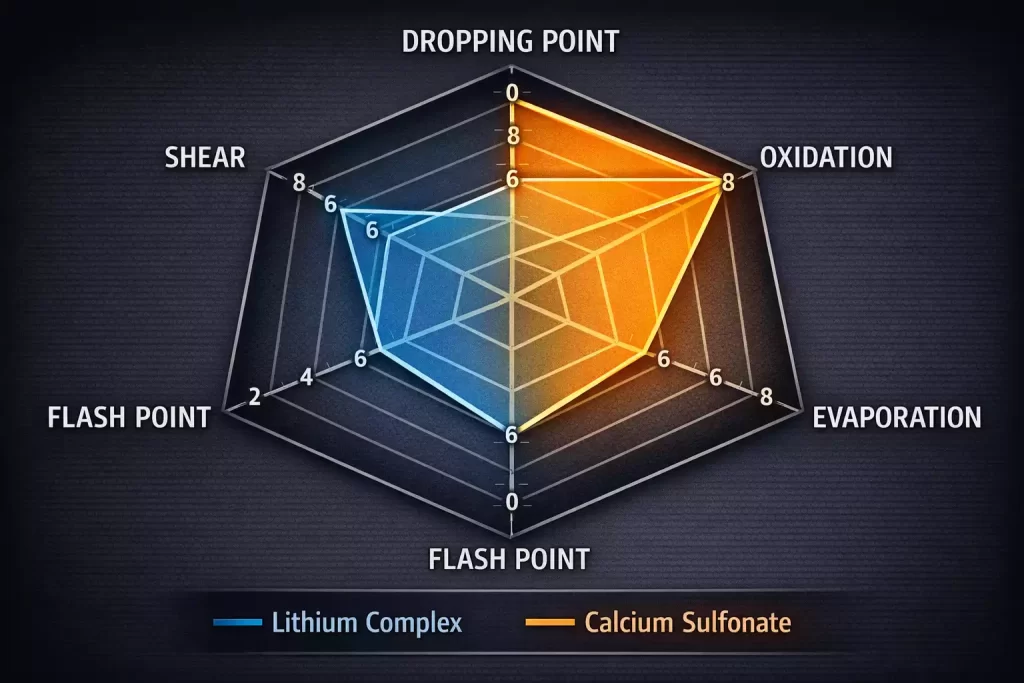

The Multi-Dimensional Selection Matrix

Stop selecting on dropping point alone.

📊 [ MARKER 4: Complete Selection Matrix]

| Selection Factor | Weight | How to Measure | Target Value |

|---|---|---|---|

| Dropping Point | 30% | ASTM D2265 | >Operating Temp + 50°C min |

| Oxidation Stability | 25% | ASTM D942 (Pressure drop) | <15 psi @100 hrs |

| Evaporation Loss | 20% | ASTM D972/D5800 (NOACK) | <10% @200°C |

| Shear Stability | 15% | ASTM D217 (Worked penetration) | <15% change after 100,000 strokes |

| Base Oil Flash Point | 10% | ASTM D92 | >Operating Temp + 40°C |

[Data Source: 2026 NLGI & SKF Joint Lubrication Engineering Guide]

How to use this:

- Get test data from supplier (demand it—don’t accept “meets spec”)

- Score each factor (1-10)

- Multiply by weight

- Total score >70 = acceptable, >85 = excellent

Practical Implementation: The 5-Minute Quick Check

For New Engineers (Speed Guide)

Step 1: Find grease dropping point on datasheet

Step 2: Subtract 50°C → This is your base safe temp

Step 3: Measure actual bearing temperature (infrared gun, $40)

Step 4: Compare:

- ✅ Actual < Safe → Continue

- ⚠️ Actual = Safe → Monitor closely

- ❌ Actual > Safe → Change grease immediately

For Experienced Engineers (Precision Method)

Use the dynamic calculator with all four factors:

- Base derating (thickener type)

- DN value adjustment

- Load adjustment

- Base oil bonus/penalty

Then validate with:

- Vibration trending (>15% increase = lubrication issue)

- Temperature trending (>10°C increase = film thickness loss)

- Visual inspection (hardening at seals = oxidation starting)

Real Failure Analysis: The $45,000 Lesson

Case: Cement Kiln Support Roller

Grease: Generic lithium complex (260°C dropping point)

Operating temp: 215°C

Expected life: 6 months

Actual life: 3 weeks

Autopsy:

- FTIR analysis: Severe oxidation

- Remaining grease: NLGI 6+ (rock hard)

- Base oil: Completely evaporated

- Soap structure: Carbonized

Root cause: Operating at 215°C with grease safe to 200°C max (260°C – 60°C derating).

Solution: Switched to Zhongtian calcium sulfonate (320°C+ dropping point, safe to 260°C). 18+ months, zero issues.

Cost comparison:

- Bearing replacement: $8,000

- Downtime: $37,000 (18 hours @ $2,000/hr)

- Total failure cost: $45,000

- Cost difference in grease: $250/year

[Data Source: Customer Maintenance Records, Anonymized]

The TCO Reality Check

Don’t Look at $/kg—Look at This:

📊 [MARKER 5: 3-Year TCO Comparison (20 Bearing Points)]

| Cost Component | Lithium Complex | Calcium Sulfonate | Savings |

|---|---|---|---|

| Grease Purchase | $4,800 | $7,200 | -$2,400 |

| Labor (Regreasing) | $18,000 | $4,500 | +$13,500 |

| Bearing Replacements | $36,000 | $6,000 | +$30,000 |

| Downtime | $96,000 | $16,000 | +$80,000 |

| TOTAL 3-Year Cost | $154,800 | $33,700 | $121,100 |

Payback period: 2.3 months

[Data Source: Composite analysis from 15 industrial facilities, 2024-2025]

Conclusion: Engineering Over Marketing

The takeaway is brutal:

Dropping point is a laboratory curiosity, not an operating limit. Using it without proper derating is gambling with bearing life.

The engineering approach:

- Know actual temperature (thermal imaging, not guessing)

- Apply multi-factor derating (not just -50°C blanket rule)

- Demand test data (oxidation, evaporation, not just drop point)

- Calculate TCO (not $/kg)

- Run pilot tests (10-20 bearings, 6 months validation)

At Zhongtian Petrochemical, we maintain strict batch-to-batch consistency across our 200,000-ton annual production using real-time viscosity monitoring and automated dosing—critical for high-temp applications where even 5°C variation matters. But we also acknowledge: if you’re running <150°C in sealed systems, our premium calcium sulfonate is overkill. [Quality System: ISO 9001:2015 Certified]

We solve high-temperature lubrication problems, not sell unnecessary upgrades.

Final CTA: Stop Trusting Datasheets Alone

🧮 Use the Dynamic Calculator – Factor in DN, load, base oil

📥 [Download: Multi-Dimensional Selection Matrix (PDF)] – Complete scoring system

💬 Have a specific application >200°C? Share your parameters below.

The difference between 260°C dropping point and 200°C safe operating limit?

That’s the difference between engineering and marketing.