Introduction: Why the Right Supplier Matters

Selecting the right industrial lubricant supplier goes far beyond finding the lowest price. Your choice impacts equipment uptime, maintenance costs, environmental compliance, and overall production efficiency. In this guide, you will learn the ten most important factors—ranging from product quality and technical support to sustainability and logistics—that ensure you partner with a supplier who adds real value. By the end, you’ll be equipped to make an informed decision that keeps your operations running smoothly, safely, and cost-effectively.

Core Factors to Evaluate Your Industrial Lubricant Supplier

1. Product Quality and Certification

- Industry Standards: Verify ISO, API, and OEM certifications to confirm lubricants meet or exceed machinery requirements.

- Consistent Quality Control: Look for suppliers with in-house testing labs or third-party audits guaranteeing batch-to-batch consistency.

2. Technical Support and Service

- Expert Guidance: A top supplier offers personalized product selection, application advice, and troubleshooting.

- Responsive After-Sales: Ask about guaranteed response times, on-site support availability, and training programs.

3. Price and Cost-Effectiveness

- Total Cost of Ownership: Compare not just unit price, but service life, refill intervals, and downtime costs.

- Volume Discounts & Incentives: Negotiate long-term contracts or bulk-order terms to improve ROI.

4. Supply Chain Stability

- Inventory Management: Ensure the supplier can meet peak-season demands without backorders.

- Alternative Sourcing: Confirm contingency plans—cross-docking, multiple manufacturing sites—to handle emergencies.

5. Environmental Protection and Sustainability

- Regulatory Compliance: Choose suppliers whose products meet local and international environmental laws (e.g., REACH, EPA).

- Green Initiatives: Prioritize companies using renewable base oils and minimal, recyclable packaging.

6. Brand Reputation and History

- Market Presence: Review customer testimonials, case studies, and third-party rankings to gauge reliability.

- Longevity: Established suppliers often offer robust R&D, stable pricing, and proven track records.

7. Customization Capabilities

- Bespoke Formulations: If your equipment requires special additives or viscosities, confirm the supplier’s R&D and scale-up capabilities.

- Testing & Validation: Look for on-site pilot batches and performance trials before full-scale production.

8. Contracts and Terms

- Clear SLAs: Contracts should define quality specs, lead times, payment methods, and penalties.

- Protective Clauses: Include quality guarantees and liquidated damages to safeguard against under-performance.

H3: 9. Geographic Location and Logistics

- Reduced Transit Time: Closer suppliers mean lower freight costs and faster deliveries.

- Distribution Network: Confirm carrier partnerships, drop-ship options, and order-tracking systems.

10. Building a Long-Term Partnership

- Strategic Alliances: Long-term relationships can unlock better pricing, innovative R&D collaboration, and priority service.

- Regular Reviews: Schedule quarterly performance audits and adjust KPIs to maintain alignment.

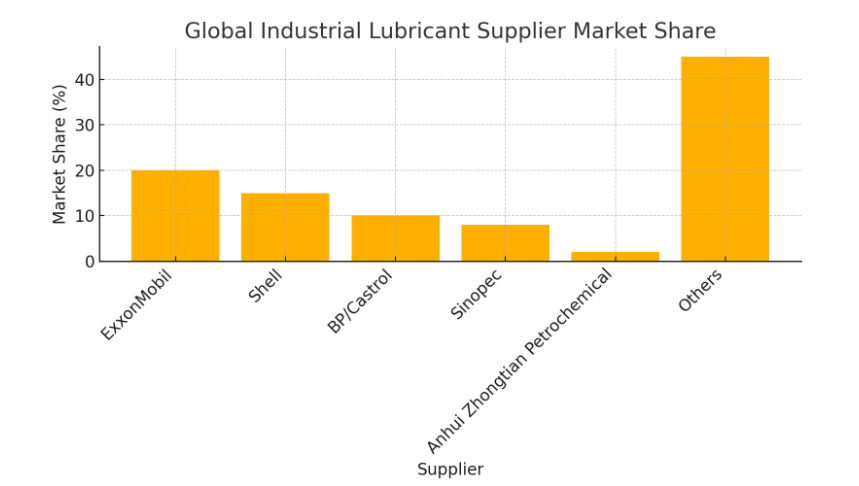

Below is a snapshot of the global market share among leading industrial lubricant suppliers—illustrating why local support and niche expertise matter beyond the big five.

Action Call

Choosing an industrial lubricant supplier is a strategic decision with far-reaching operational and financial consequences. By rigorously evaluating quality certifications, technical support, cost-effectiveness, supply chain robustness, sustainability, and more, you will align with a partner that truly enhances your bottom line.

Next Steps:

- Request Samples & Data Sheets: Compare real-world performance under your exact operating conditions.

- Schedule a Technical Audit: Invite shortlisted suppliers for on-site lubrication studies.

- Negotiate a Pilot Contract: Test service levels, delivery reliability, and after-sales responsiveness before committing long term.