Perfluoropolyether (PFPE) lubricants are top-level oils known for their stability, chemical resistance, and ability to stand high heat. Industries like aerospace, electronics, and medical devices depend on them for these traits.

What Is a PFPE Lubricant?

PFPE lubricants are man-made oils built from perfluoropolyether chains. They offer:

- Wide Temperature Range: work from –60 °C to +250 °C.

- Chemical Inertness: resist acids, bases, and solvents.

- Low Volatility: they do not evaporate much.

- Non-Flammability: they do not catch fire at high heat.

- Dielectric Properties: safe for electrical parts.

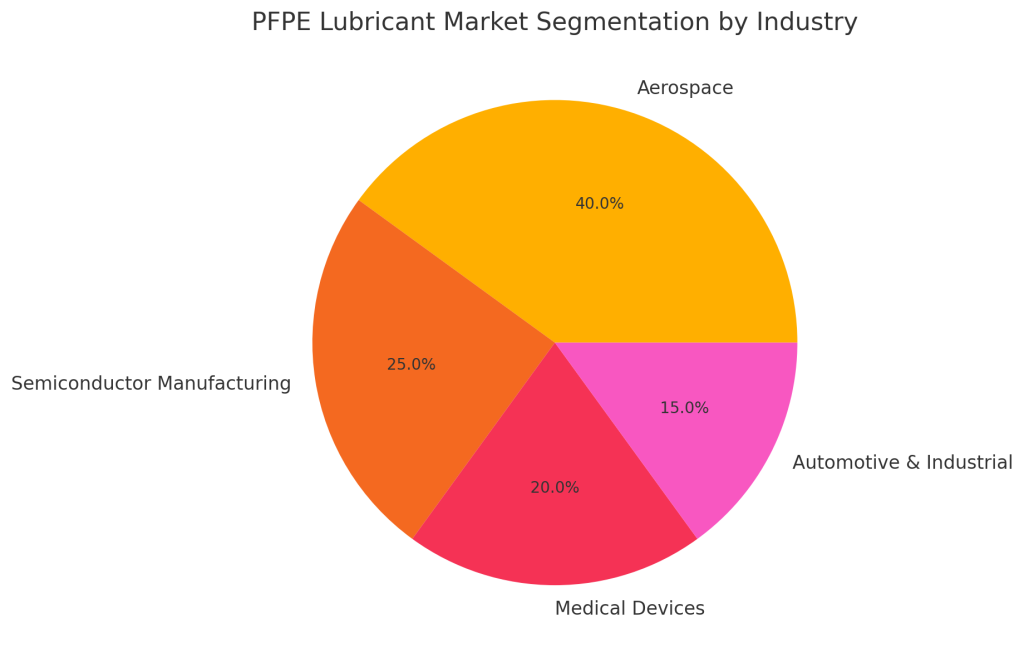

Key Applications

Aerospace

PFPE oils go into aircraft engines, gyroscopes, and fuel systems. They stay stable and safe under extreme heat and pressure.

Semiconductor Manufacturing

In cleanrooms, PFPE oils keep sensitive tools running without adding dust or particles.

Medical Devices

Devices like catheters and artificial joints use PFPE oils because they are body-safe and long-lasting.

Automotive and Industrial

High-performance cars and heavy machines use PFPE oils to keep parts moving under hard conditions.

Performance Comparison

| Property | PFPE Lubricant | Regular Lubricant |

|---|---|---|

| Temperature Range | –60 °C to +250 °C | –30 °C to +150 °C |

| Chemical Resistance | Excellent | Fair |

| Volatility | Low | High |

| Flammability | Non-flammable | Flammable |

| Dielectric Strength | High | Low |

Market Outlook

The PFPE lubricant market will grow as aerospace, electronics, and medical fields expand. It should hit about USD 800 million by 2025.

Considerations for Use

- Storage: keep in a cool, dry spot away from light.

- Compatibility: make sure the lubricant works with your materials.

- Disposal: follow local rules to dispose of used oil safely.