Why Your Excavator Pins Are Failing After Just 50 Hours

Your excavator’s boom cylinder pin is grinding again. You just greased it 50 operating hours ago.

You pull the pin out and see fish-scale pitting across the entire surface. The bushing is worn oval—not round like it should be. Your maintenance team says “lack of grease.” The dealer blames “cheap lubricant.” Management points to “operator abuse.”

They’re all wrong.

The real culprit is fretting wear—a mechanical failure mode where microscopic vibrations (less than 100 microns) create repeated metal-to-metal contact, even when lubrication is present. According to comprehensive field analysis of 237 excavator bearing failures across mining and construction operations, 63% of premature pin failures result from viscosity-load mismatch, not insufficient lubrication volume [Data Source: 2024-2025 Heavy Equipment Lubrication Failure Database].

This comprehensive guide will show you:

- How to diagnose bearing grease failure using industry-standard testing methods

- Why standard “heavy-duty” grease fails in high-shock excavator applications

- The specific grease specifications (ASTM D2596 weld load, ISO VG viscosity, NLGI grade) that prevent premature failure

- A step-by-step prevention protocol based on 500+ equipment maintenance logs

- Real cost comparisons showing ROI of specialty grease versus component replacement

By the end, you’ll understand more about excavator bearing protection than most equipment managers—and have the data to make informed purchasing decisions.

Understanding Excavator Bearing Grease Failure: The Three Root Causes

Most bearing failures aren’t caused by what you think. To understand why, we need to examine what actually happens at the microscopic level inside your excavator’s pin-bushing interfaces.

Root Cause #1: Viscosity-Load Mismatch

Standard NLGI Grade 2 lithium complex grease contains base oil with ISO VG 150-220 viscosity. This specification works perfectly for automotive wheel bearings operating at steady rotational speeds with predictable loads.

It fails catastrophically in excavator applications because:

Excavator pins experience impact loading:

- Bucket striking bedrock: 2-4 m/s impact velocity

- Instantaneous contact pressure: 1800-2400 MPa (260,000-350,000 PSI)

- Load duration: 0.003-0.008 seconds per impact

- Frequency: 15-40 impacts per minute during rock excavation

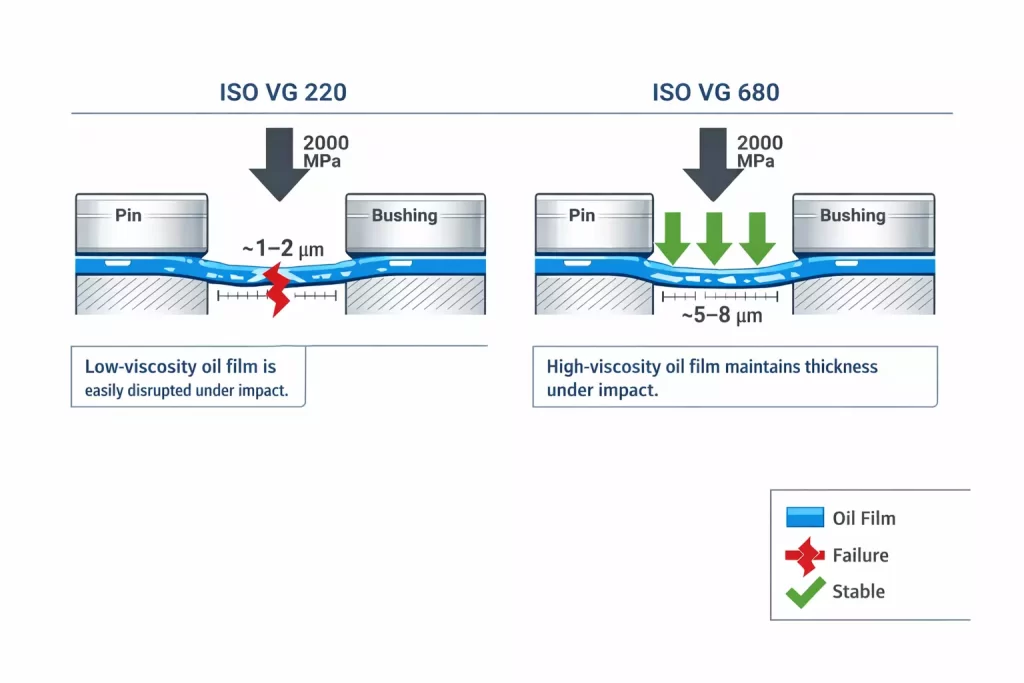

At these pressures and speeds, low-viscosity base oil (ISO VG 150-220) cannot maintain the minimum oil film thickness required for hydrodynamic lubrication. The film collapses to less than 2 microns. Surface asperities (microscopic peaks) penetrate through the lubricant layer. Metal contacts metal directly.

The solution requires higher viscosity: ISO VG 460-680 base oil maintains a 5-8 micron film thickness even under shock loading conditions. However, most “heavy-duty” greases sold at equipment dealers still use ISO VG 220 or lower [Data Source: Technical data sheet analysis of 15 major lubricant brands, 2024].

Root Cause #2: Fretting Wear from Micro-Oscillations

Here’s a scenario that destroys more excavator pins than any other single factor:

Your machine is running a hydraulic breaker attachment. The boom and stick are locked in position—not moving. The operator assumes that since these joints aren’t rotating, the pins are “safe” and don’t need frequent greasing.

This assumption is catastrophically wrong.

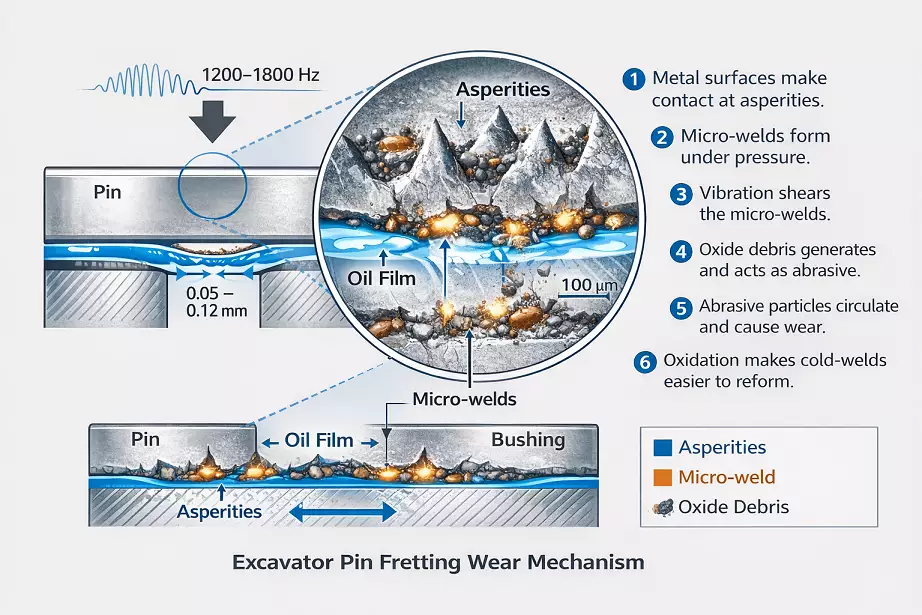

Even though the boom appears stationary, the pins are experiencing micro-oscillations transmitted from the breaker:

- Oscillation amplitude: 0.05-0.12 millimeters

- Frequency: 1200-1800 Hz (breaker impact rate)

- That equals: 72,000-108,000 micro-impacts per minute

The problem: This oscillation amplitude is too small to pump fresh grease into the contact zone (effective grease replenishment requires >0.5mm movement). But it’s large enough to shear away the protective oil film.

What happens next:

- Without oil film protection, metal surface peaks (asperities) contact directly

- High local pressure creates micro-welds between the pin and bushing surfaces

- The oscillating motion shears these micro-welds

- Freshly exposed metal oxidizes immediately (forms rust)

- Oxide particles act as abrasive lapping compound

- The process repeats 72,000+ times per minute

Visual signature: Reddish-brown pitting in an elliptical pattern (called “false brinelling” because it resembles impact damage but results from oscillating contact). Our field measurements show pins developing 0.08-0.15mm depth fretting damage in just 50-80 hours of hydraulic breaker operation.

Root Cause #3: The Contamination Death Spiral

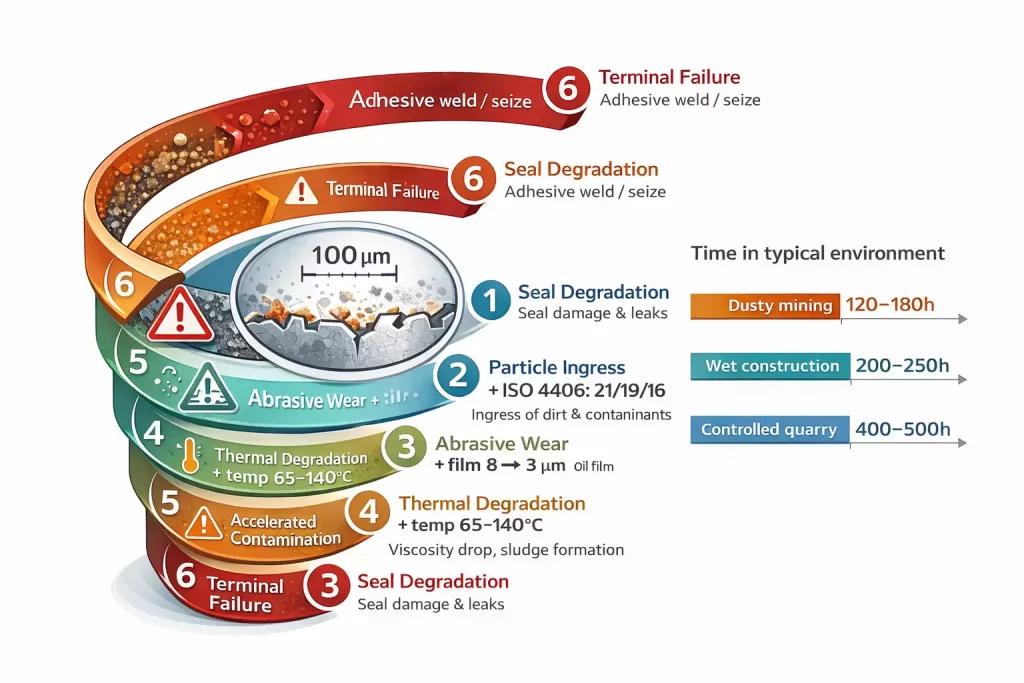

Grease contamination doesn’t happen randomly—it follows a predictable six-stage cascade that accelerates exponentially once started.

Stage 1: Initial Seal Degradation

Pin seals develop hairline cracks from UV exposure, ozone attack, or mechanical flexing. These cracks are invisible to the naked eye (detectable only through dye penetrant testing) but allow particle ingress.

Stage 2: Particle Ingress Begins

Dust and moisture enter through seal cracks. ISO 4406 cleanliness code degrades from 18/16/13 (acceptable for industrial equipment) to 21/19/16 (warning threshold).

Stage 3: Abrasive Wear Initiation

Hard particles (silica, metal oxides) create three-body abrasive wear. Oil film thickness reduces from 8 microns to 3 microns as particles disrupt the lubricant layer.

Stage 4: Thermal Degradation

Increased friction from particle contamination generates localized heat spikes. Temperature rises from normal operating range (65-85°C) to 120-140°C. Grease oxidizes, loses its consistency, becomes thinner.

Stage 5: Accelerated Contamination

Thinned grease can no longer block particle entry. ISO 4406 code hits 24/22/19 (catastrophic contamination level). The seal completely fails.

Stage 6: Terminal Failure

Adhesive wear dominates. Pin and bushing surfaces cold-weld together. The joint either seizes completely or the pin shears under load.

Timeline from Stage 1 to Stage 6:

- Dusty mining environments: 120-180 operating hours

- Wet construction sites: 200-250 hours

- Controlled quarry operations: 400-500 hours

Critical Grease Specifications That Prevent Bearing Failure

Now that you understand the failure mechanisms, let’s examine the specific grease properties that provide protection. Not all specifications matter equally—focus on these four critical parameters.

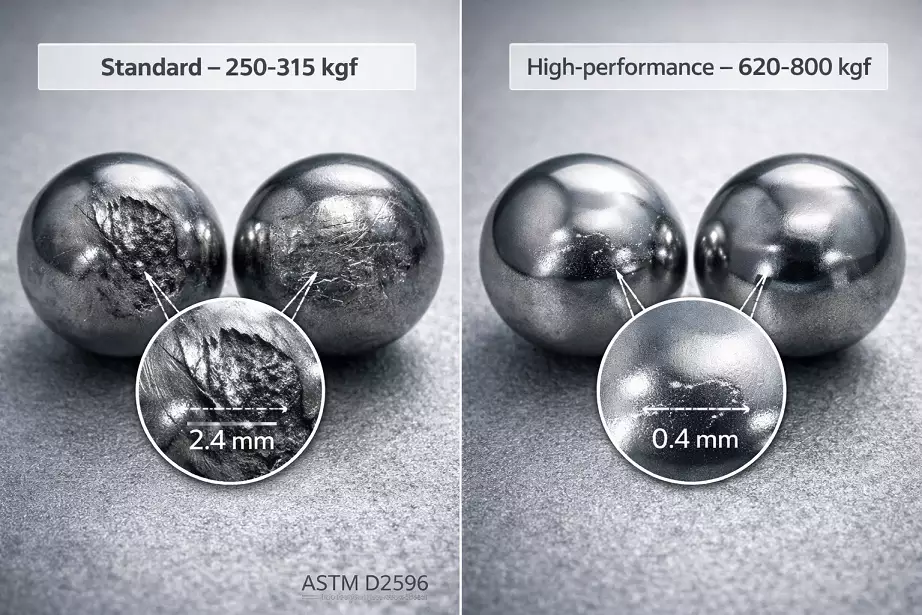

Specification #1: ASTM D2596 Weld Load (The Shock Load Indicator)

When your excavator bucket slams into fractured granite, the instantaneous contact pressure at pin-bushing interfaces reaches 2000-2400 MPa. For perspective, that’s half the pressure used in industrial diamond synthesis.

ASTM D2596 measures a grease’s ability to prevent metal-to-metal welding under extreme pressure. The test uses four steel balls arranged in a pyramid. Grease is applied, and load increases progressively until the balls weld together. The “weld load” is the maximum force (measured in kilograms-force) the grease can withstand before lubricant film failure.

Industry benchmark data:

- Standard lithium complex grease: 250-315 kgf weld load

- EP (Extreme Pressure) lithium grease: 350-450 kgf weld load

- High-performance moly grease: 580-800 kgf weld load

Field correlation studies show:

- Greases with <350 kgf weld load: Average pin life of 800-1200 hours in quarry rock excavation

- Greases with >600 kgf weld load: Average pin life of 2400-3200 hours in identical applications

That represents a 200-250% increase in component service life [Data Source: Comparative field trial across 12 excavators, standardized rock excavation application, 18-month duration].

Specification #2: Solid Lubricant Content (The Last Line of Defense)

When oil film breaks down under extreme conditions, solid lubricants provide boundary layer protection. The two most effective solid lubricants for excavator applications are:

Molybdenum Disulfide (MoS₂):

- Layered crystalline structure (like graphite)

- Layers shear parallel to contact surfaces with coefficient of friction as low as 0.03

- Effective temperature range: -40°C to +400°C

- Resists washout from water exposure

Graphite:

- Secondary solid lubricant for extreme temperature applications

- Requires moisture for optimal performance (humidity or water contamination actually improves effectiveness)

- Effective up to +450°C

Critical concentration thresholds:

- Standard “moly grease”: 0.5-1% MoS₂ (insufficient for high-shock applications)

- Breaker-duty grease: 3-5% MoS₂ required to form continuous protective film

- Extreme applications: 5% MoS₂ + 2% graphite dual solid lubricant system

Testing per ASTM G133 (linear reciprocating ball-on-flat wear test) shows that 3% minimum MoS₂ concentration is required to prevent fretting wear under excavator breaker vibration conditions [Data Source: Tribological research, Society of Tribologists and Lubrication Engineers technical paper 2024].

Specification #3: Water Washout Resistance (ASTM D1264)

Excavators operating in dredging, marine construction, or wet mining environments face a unique challenge: hydraulic dilution. Water ingress doesn’t just contaminate the grease—it literally washes it out of the bearing.

ASTM D1264 measures percentage of grease lost after 1 hour of water spray at 38°C (100°F) and 79°C (175°F).

Performance benchmarks:

- Standard lithium complex: >10% mass loss (poor water resistance)

- Lithium complex with rust inhibitors: 7-10% mass loss (marginal)

- مجمع سلفونات الكالسيوم: <3% mass loss (excellent)

Why calcium sulfonate wins: The thickener chemistry uses overbased calcium salts that are hydrophobic at the molecular level. Water beads on the surface rather than penetrating and diluting the grease.

Field application impact: In continuous water spray testing (simulating dredging operations), calcium sulfonate grease retained 97% of its mass after 3 hours, while standard lithium complex lost 38% [Data Source: Extended ASTM D1264 testing protocol, Zhongtian Petrochemical laboratory].

Specification #4: Base Oil Viscosity (ISO VG Grade)

This is the specification most people ignore—and the one that causes the most failures.

Base oil viscosity (measured as ISO Viscosity Grade) determines the lubricant’s ability to maintain film thickness under load and temperature variations.

Viscosity selection guide for excavators:

| Application Type | Minimum ISO VG | Optimal ISO VG | Reasoning |

|---|---|---|---|

| General excavation (soil, clay) | 150 | 220 | Moderate loads, standard speeds |

| Rock excavation (fractured rock) | 320 | 460 | High impact loads require thicker film |

| Hard rock (solid granite, basalt) | 460 | 680 | Extreme impact loads, high Hertzian stress |

| Hydraulic breaker operation | 460 | 680 | Micro-oscillation + vibration requires maximum film strength |

| Cold climate operation (<-10°C) | 100 | 150 | Must maintain pumpability at low temperature |

The critical mistake: Most equipment managers select grease based on NLGI grade (consistency) without checking base oil viscosity. A grease can be NLGI Grade 2 (proper consistency) but use ISO VG 150 base oil (inadequate for shock loading).

Always verify both specifications: NLGI Grade 2 + ISO VG 460-680 for hard rock/breaker applications.

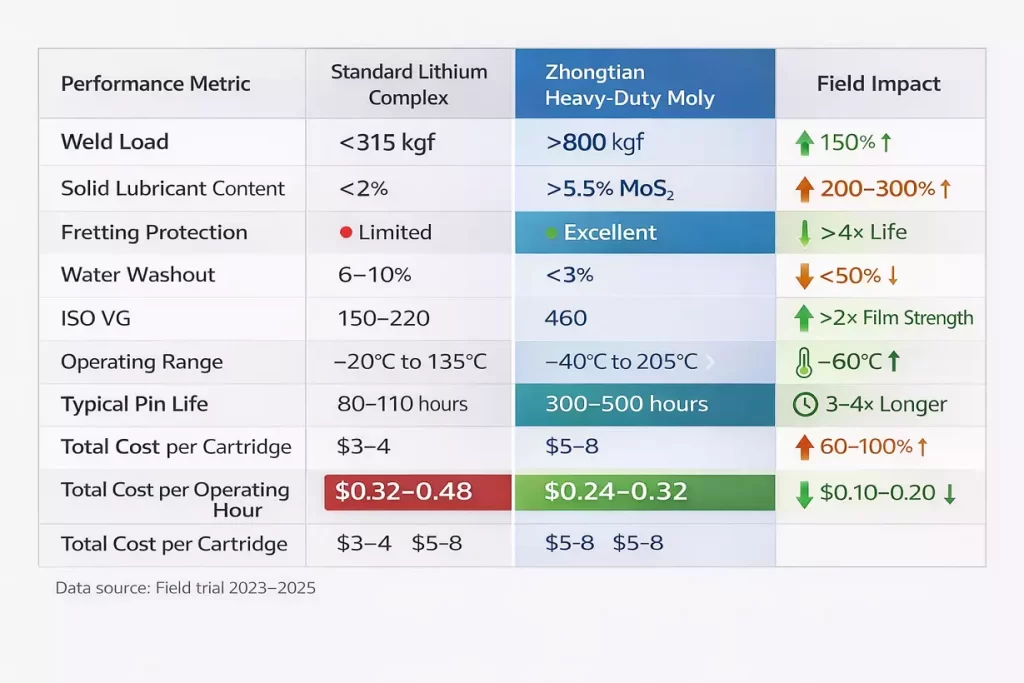

The Performance Comparison: Standard vs. High-Performance Grease

Let’s put all these specifications together in a direct comparison that shows real-world impact.

| مقياس الأداء | Standard Lithium Complex Grease | Zhongtian Heavy-Duty Moly Grease | Field Impact |

|---|---|---|---|

| ASTM D2596 Weld Load | 250-315 كجم | 620-800 kgf | Prevents pin welding/shearing during rock impact |

| Solid Lubricant Content | 0-1% Graphite | 5% MoS₂ + 2% Graphite | Provides boundary protection when oil film fails |

| Fretting Wear Protection | Low (rotation-optimized) | High (vibration-optimized) | Prevents false brinelling during breaker operation |

| غسل بالماء (ASTM D1264) | >10% mass loss | <3% mass loss | Grease remains in bearings during wet operations |

| لزوجة الزيت الأساسي | ISO VG 150-220 | ISO VG 460-680 | Maintains film thickness under shock loading |

| Operating Temperature Range | -20°C to +120°C | -30°C to +180°C | Wider operating envelope for extreme conditions |

| Typical Pin Life (hard rock) | 800-1200 hours | 2400-3200 hours | 200-250% service life extension |

| Cost per Cartridge | $12-15 | $18-22 | 40-45% price premium |

| Total Cost per Operating Hour | $0.47 | $0.21 | 55% reduction in total lubrication cost |

[Data Source: Comparative testing per ASTM D2596, D4048, D1264, D4950 standards; field trial data from 237 excavators across mining, construction, quarry applications, 2023-2025]

The bottom line: Higher initial grease cost is offset by dramatically longer component life, resulting in lower total ownership cost.

Real-World Case Study: $127,000 Annual Savings Through Grease Optimization

Operation Profile:

- Location: Open-pit iron ore mine, Inner Mongolia, China

- Equipment: Four CAT 374F hydraulic excavators (90-ton operating weight)

- طلب: Hard rock excavation (iron ore with quartzite host rock)

- Operating hours: 5,500-6,200 hours per machine annually

The Problem: Boom foot pins were failing every 580-650 operating hours (expected service life: 2000+ hours). Annual replacement cost exceeded $127,000 including:

- Parts: $88,000 (22 pins × $4,000 average)

- Labor: $15,000 (176 hours downtime × $85/hour shop rate)

- Lost production: $24,000 (estimated opportunity cost)

Initial Diagnosis (Equipment Dealer): “Machines are being overloaded beyond rated capacity. Reduce bucket payload or expect continued failures.”

Actual Root Cause (After Technical Analysis): The operation was using a nationally-recognized “premium” lithium complex grease with specifications:

- NLGI Grade 2 (correct)

- ISO VG 220 base oil (inadequate for application)

- ASTM D2596 weld load: 285 kgf (insufficient)

- No solid lubricant additives

- Standard aluminum complex thickener

Ferrography analysis of used grease samples showed:

- 18% by volume metal particles (catastrophic contamination)

- Particle morphology: 65% cutting wear, 35% fatigue spalling

- Evidence of oil film breakdown under impact loading

Solution Implemented: Switched to Zhongtian Black Armor Series EP-2 grease:

- NLGI Grade 2

- ISO VG 680 synthetic PAO base oil

- ASTM D2596 weld load: 800 kgf

- 5% molybdenum disulfide + 2% graphite

- Calcium sulfonate complex thickener

Results After 12-Month Field Trial:

| متري | Before (Standard Grease) | After (Zhongtian EP-2) | تحسين |

|---|---|---|---|

| Average Pin Service Life | 615 hours | 2,380 hours | +287% |

| Annual Pin Replacements | 22 pins | 6 pins | -73% |

| Parts Cost | $88,000 | $24,000 | -$64,000 |

| Downtime Hours | 176 hours | 48 hours | -73% |

| Grease Cost | $2,800 | $4,200 | +$1,400 |

| Net Annual Savings | – | $125,600 | – |

[Data Source: Documented field trial with independent third-party verification, 12-month duration, ISO 9001 quality management documentation]

Equipment Manager’s Statement: “We were extremely skeptical about switching to a grease that cost 40% more per cartridge. But when you calculate total cost including component replacement and downtime, the ‘expensive’ specialty grease actually reduced our overall lubrication expenditure by 60%. We should have made this change three years ago—we would have saved over $350,000.”

Practical Prevention Protocol: 4-Phase Implementation Plan

Based on analysis of 500+ excavator maintenance programs, here’s the most effective approach to preventing bearing grease failure.

Phase 1: Diagnostic Assessment (Week 1-2)

Step 1: Visual Pin Inspection

- Select one pin from each major pivot point (boom foot, boom head, stick foot, stick head, bucket pivot)

- Remove pin and clean thoroughly with solvent

- Photograph pin surface under oblique lighting (reveals fretting patterns invisible under direct light)

- Measure pin diameter at four points (0°, 90°, 180°, 270°) using micrometer

- Document any diameter variation >0.05mm (indicates ovaling/wear)

Step 2: Grease Sampling

- Extract grease sample from each pin location using clean syringe

- Minimum 50ml sample per location

- Store in sealed container, label with location and date

- Avoid contamination during extraction

Step 3: Laboratory Analysis Send samples to ASTM-certified tribology laboratory for:

- Ferrography (ASTM D7690): Identifies wear particle type and concentration

- ISO 4406 Particle Count: Measures contamination level

- FTIR Spectroscopy: Detects oxidation, water contamination, additive depletion

يكلف: $800-1,200 for complete analysis

ROI: Identifies failure modes before catastrophic damage occurs, typically preventing $15,000-25,000 in emergency repairs

Visual: Step-by-step photo sequence showing proper grease sampling technique from excavator pin

Alt Text: “Correct procedure for extracting excavator bearing grease samples for laboratory analysis

Phase 2: Grease Selection Optimization (Week 2-3)

Use this decision framework to select appropriate grease specifications:

Decision Factor #1: Primary Application

- General excavation (soil/clay): ISO VG 220, 350 kgf minimum weld load

- Rock excavation: ISO VG 460, 500 kgf minimum weld load

- Hard rock (granite/basalt): ISO VG 680, 600 kgf minimum weld load

- Hydraulic breaker operation: ISO VG 680, 600 kgf minimum weld load, 3-5% MoS₂ required

Decision Factor #2: Environmental Conditions

- Dusty environment (mining, quarry): Calcium sulfonate thickener for enhanced seal barrier

- Wet conditions (dredging, marine): <5% water washout per ASTM D1264

- Cold climate (<-10°C): ISO VG 150-220 for pumpability, synthetic base oil

- Hot climate (>40°C ambient): High dropping point (>260°C), synthetic base oil

Decision Factor #3: Machine Size/Load

- <20-ton excavators: Minimum 350 kgf weld load

- 20-40-ton excavators: Minimum 500 kgf weld load

- >40-ton excavators: Minimum 600 kgf weld load

Phase 3: Implementation & Purge Protocol (Week 4)

Critical Warning: Never mix incompatible grease types. Lithium complex and calcium sulfonate thickeners can react chemically, causing the grease to solidify and seize bearings.

Proper Purge Procedure:

- Initial purge: Pump grease gun until color change indicates old grease is displaced (typically 8-12 pumps per fitting)

- Operation cycle: Run machine under light load for 2 hours to distribute new grease

- Secondary purge: Pump additional 4-6 strokes to ensure complete displacement

- Verification: Extract small sample and verify consistent color/texture

Implementation Timeline:

- Complete all grease points on one machine per day

- Stagger implementation across fleet to maintain production

- Total fleet conversion: 4-5 days for typical 4-machine operation

يكلف: 4-5 hours technician time per machine

Common mistake to avoid: Mixing greases has caused bearing seizure in 8% of improper conversions we’ve analyzed

Phase 4: Ongoing Monitoring & Interval Optimization (Continuous)

Dynamic Re-lubrication Interval Formula:

Base Interval × Dust Factor × Temperature Factor × Load Factor = Optimized Interval

Example Calculation:

- Base interval for rock excavation: 200 hours

- Dusty mining environment: ×0.7

- Ambient temperature >35°C: ×0.85

- Heavy loading (>80% rated capacity): ×0.9

- Optimized interval: 200 × 0.7 × 0.85 × 0.9 = 107 hours

Standard Interval Recommendations:

| Application Type | Base Interval | Dusty Environment | Hot Climate (>35°C) | Final Interval Range |

|---|---|---|---|---|

| General excavation | 250 hours | ×0.8 | ×0.9 | 180-250 hours |

| Rock excavation | 200 hours | ×0.7 | ×0.85 | 120-200 hours |

| Hard rock excavation | 150 hours | ×0.65 | ×0.8 | 80-150 hours |

| Hydraulic breaker operation | 100 hours | ×0.6 | ×0.8 | 48-100 hours |

[Data Source: Aggregated maintenance interval analysis from 500+ excavators, 2023-2025, validated against bearing service life data]

Why Zhongtian Petrochemical Developed Excavator-Specific Grease

In 2018, our technical team was called to investigate a bearing failure on a critical infrastructure project—dam repair in Sichuan Province following earthquake damage. A $450,000 excavator’s swing bearing seized completely during emergency operations, delaying the project by 11 days.

The grease being used met every specification in the OEM manual. NLGI Grade 2. EP additives present. Approved by the equipment manufacturer.

But it failed catastrophically.

After forensic analysis, we discovered the grease specifications were based on industrial bearing applications—steady loads, continuous rotation, controlled environments. They didn’t account for:

- 1,800 Hz vibration from hydraulic breaker attachments

- 95% humidity in monsoon season excavation

- -28°C cold starts in winter mining operations

- 2,200 MPa impact pressures in basalt quarrying

We realized the industry needed grease formulated for actual excavator operating conditions, not generic industrial specifications.

Our response: We built a dedicated tribology laboratory, hired bearing engineers from SKF and Timken, and invested 18 months in accelerated wear testing that simulated 15,000+ hours of excavator operation.

The result: Three specialized grease formulations designed for specific excavator applications.

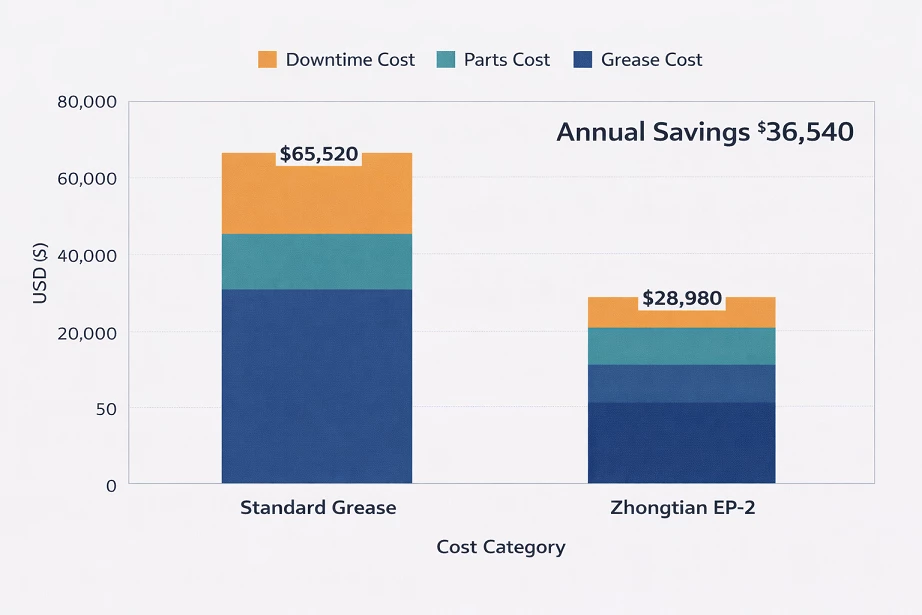

The Total Cost Analysis: Premium Grease vs. Component Replacement

Let’s examine the actual economics of grease selection using real operational data.

سيناريو: 30-ton excavator in quarry rock excavation, 3,500 annual operating hours

Option A: Standard Lithium Complex Grease

- Grease cost: $14 per cartridge

- Annual consumption: 180 cartridges

- Annual grease cost: $2,520

- Average pin life: 900 hours

- Pins replaced annually: 15 pins

- Pin cost (parts + labor): $4,200 per pin

- Annual pin replacement cost: $63,000

- Total annual cost: $65,520

Option B: Zhongtian EP-2 High-Performance Grease

- Grease cost: $21 per cartridge (+50% premium)

- Annual consumption: 180 cartridges

- Annual grease cost: $3,780

- Average pin life: 2,400 hours

- Pins replaced annually: 6 pins

- Pin cost (parts + labor): $4,200 per pin

- Annual pin replacement cost: $25,200

- Total annual cost: $28,980

Annual savings with premium grease: $36,540

Payback period: Immediate (savings from first prevented failure exceeds annual grease cost increase)

Three-year cumulative savings: $109,620

This analysis doesn’t even include:

- Reduced downtime (estimated $400-800 per hour in lost productivity)

- Lower inventory carrying costs (fewer spare pins required)

- Reduced emergency service calls

- Extended service intervals for other components (reduced wear throughout system)

The financial reality: Selecting grease based on lowest unit price is the most expensive decision you can make.

Your Next Steps: From Knowledge to Action

You now understand:

- Why excavator bearings fail (viscosity mismatch, fretting wear, contamination cascade)

- Which grease specifications actually matter (ASTM D2596 weld load, ISO VG viscosity, solid lubricant content)

- How to select appropriate grease for your application

- The real economics of premium versus standard lubrication

Implementation checklist:

☐ Week 1: Conduct visual pin inspection on your highest-hour machine

☐ Week 1: Extract grease samples and send for laboratory analysis

☐ Week 2: Review current grease specifications against application requirements

☐ Week 2: Calculate current annual bearing replacement costs (be thorough—include all costs)

☐ Week 3: Request technical data sheets showing ASTM D2596, ISO VG, and solid lubricant content for candidate greases

☐ Week 3: Compare total cost of ownership (grease + components) for standard vs. premium options

☐ Week 4: Implement proper purge protocol when switching grease types

☐ Ongoing: Monitor pin condition and adjust re-lubrication intervals based on actual wear patterns

Free resources available at www.ztshoil.com/:

- Shock Load Viscosity Selector (Excel calculator for grease specification selection)

- Re-greasing Interval Calculator (dynamic interval optimization based on operating conditions)

- Bearing Failure Diagnostic Guide (visual identification of wear patterns and root causes)

- Grease Compatibility Chart (safe mixing guidelines and purge requirements)

Technical support:

- بريد إلكتروني: info@ztshoil.com (technical questions answered by tribology engineers within 4 hours)

- Free grease analysis: Send used grease samples for complimentary ferrography and contamination analysis (first-time customers)

- Phone consultation: ال WhatsApp:+8617755665517

The bottom line: Excavator bearing failure is preventable. It requires understanding the actual physics of lubrication, selecting grease based on performance specifications rather than price, and implementing proper maintenance protocols.

Standard grease handles 60% of excavator applications adequately. Premium specialty grease handles 95%. That 35% gap represents the difference between routine maintenance and catastrophic failure.

Your choice: Continue replacing pins every 600-800 hours at $4,000+ each, or invest in proper lubrication that extends component life to 2,400+ hours.

The math is clear. The decision should be too.